Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 325

TO RESUME: After disengaging the vehicle speed

control by tapping the brake pedal or clutch pedal,

push the RESUME/ACCEL button to return vehicle

to the previously set speed.

TO ACCELERATE: While vehicle speed control is

engaged, hold the RESUME/ACCEL button de-

pressed and release at a new desired speed. This will

allow the vehicle to continuously accelerate and set

at a higher speed setting.

TAP-UP: When the vehicle speed control is en-

gaged, tapping the RESUME/ACCEL button will in-

crease the speed setting by 2 mph (3 km/h). The

system will respond to multiple tap-ups.

TO ACCELERATE for PASSING: Depress the

accelerator as you would normally. When the pedal

is released the vehicle will return to the speed set-

ting in memory.

DIAGNOSIS PROCEDURES

Whenever a vehicle speed control malfunction oc-

curs, first verify that the vehicle speed control wire

harness is properly connected to all connectors before

starting normal diagnosis and repair procedures. Re-

fer to Electronic Vehicle Speed Control Diagnosis

Chart or Vehicle Speed Control Circuit (Fig. 9, 10

and 11).

A poor connection can cause a complete or inter-

mittent malfunction and is also the only connection

in the circuit, that can not be tested. For this reason,

a loose connection may be misdiagnosed as a compo-

nent malfunction.

Also, check all vacuum connections for tightness

and cracked hoses.

ROAD TEST

Road test vehicle to verify reports of vehicle speed

control malfunction. The road test should include at-

tention to the speedometer. Speedometer operation

should be smooth and without flutter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the vehicle speed con-

trol. The cause of any speedometer deficiencies

should be corrected before proceeding.

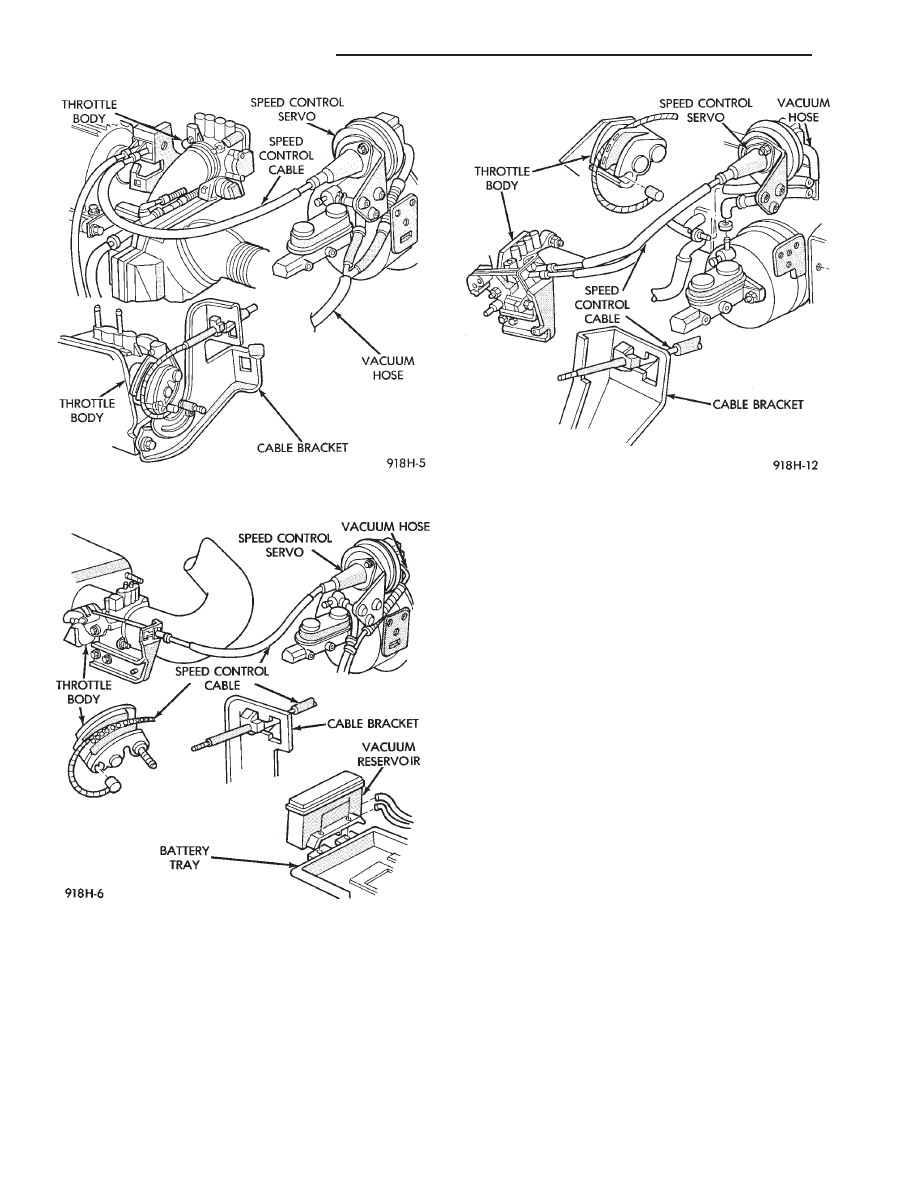

Fig. 3 Vehicle Speed Control—Turbo

Fig. 4 Vehicle Speed Control—3.0L

Fig. 5 Vehicle Speed Control—2.2L Turbo III

8H - 2

VEHICLE SPEED CONTROL

Ä

INOPERATIVE SYSTEM

If road test verifies an inoperative system with a

correct speedometer operation:

• Inspect fuse

• Check for loose electrical and vacuum connections

at the servo

• Check for correct position of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

• Inspection should also be made to verify that both

ends of the vehicle speed control cable are securely

attached. If either end is loose, the vehicle speed con-

trol will be inoperative.

CHECKING FOR FAULT CODE

(1) When trying to verify a vehicle speed control

electronic malfunction:

(a) Connect a DRB II if available.

(b) Plug DRB II into the diagnostic connector in

the engine compartment.

(c) Check that either a Fault Code 34 or Fault

Code 15 is indicated.

(d) An inoperative vehicle speed control may still

occur without either fault code being indicated.

(e) With key inserted in ignition switch, cycle

switch to ON position three times. On third cycle,

leave switch in ON position.

(f) After switch has been cycled three times, ob-

serve CHECK ENGINE indicator on instrument

cluster. If a Fault Code is present, indicator will

flash (blink) in a series which will show which

Fault Code is the problem. EXAMPLE: A series of

three flashes in rapid succession, a slight pause,

then four flashes in rapid succession would indicate

Fault Code 34.

(2) If no Fault Code appears, or Fault Code 34 is

observed, refer to:

• The Servo Electrical Test.

• The Powertrain Control Module Electrical Test.

(3) If a fault code 15 is observed, test vehicle speed

sensor.

For testing vehicle speed sensor and related compo-

nents refer to the Powertrain Diagnostics Test Proce-

dure Manual.

(4) Correct any problems found when performing

these tests and recheck for Fault Code if changes

were made.

(5) If no problems were found above, replace pow-

ertrain control module.

VEHICLE SPEED CONTROL ELECTRICAL TESTS

WARNING: IF REMOVAL OF AIR BAG MODULE IS

NECESSARY, REFER TO GROUP 8M, RESTRAINT

SYSTEMS.

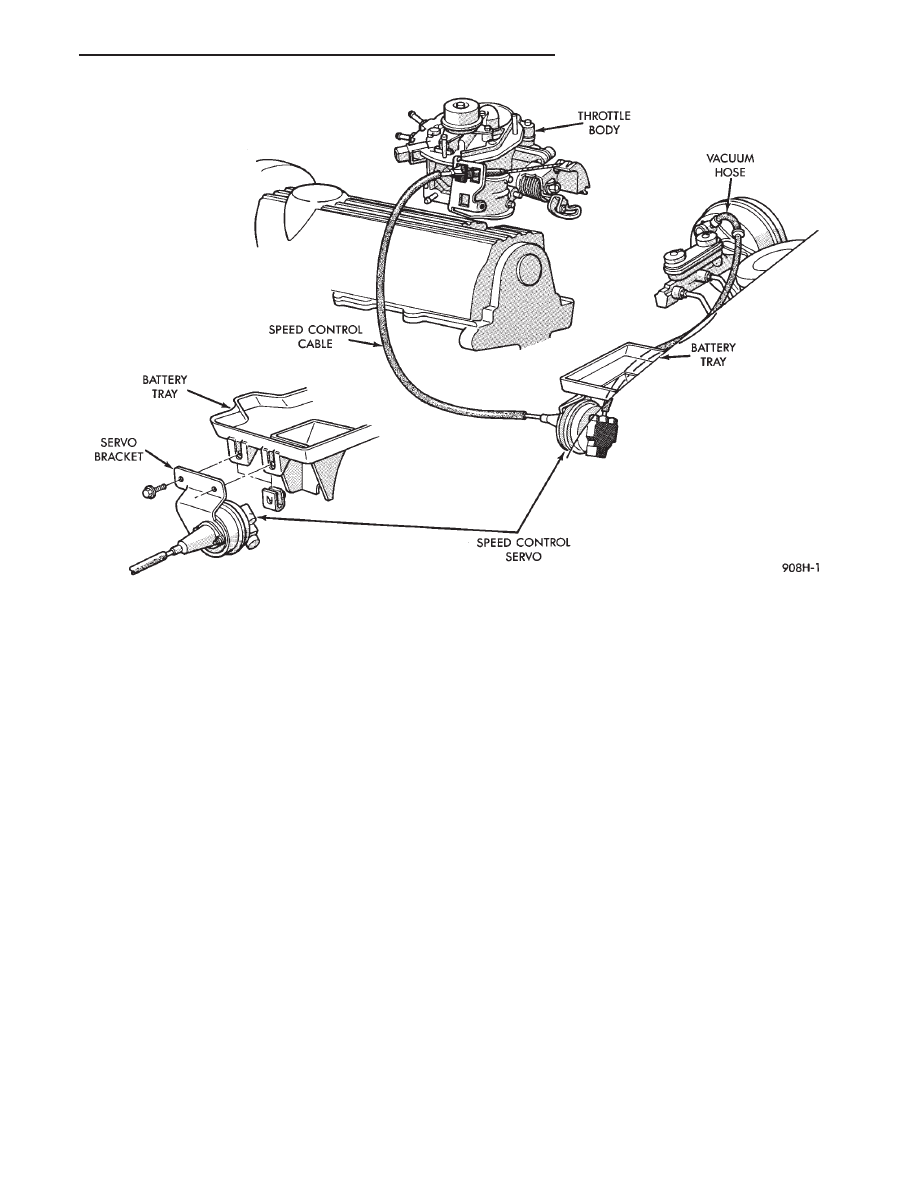

Fig. 6 Vehicle Speed Control—AC & AY Bodies with 2.5L

Ä

VEHICLE SPEED CONTROL

8H - 3

Electronic vehicle speed control may be tested us-

ing two different methods. One involves use of a

DRB II. If this test method is desired, refer to the

Powertrain Diagnostic Test Procedures for charging

and vehicle speed control manual.

The other test method uses a volt/ohm meter and is

described in the following tests.

If any information is needed concerning wiring, re-

fer to Group 8W, Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

SERVO ELECTRICAL TESTS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG,

STEERING

WHEEL

OR

COLUMN

RE-

MOVAL PROCEDURES.

(1) Turn ignition switch to the ON position. With

the vehicle speed control switch in the ON position,

set up a voltmeter to read battery voltage and con-

nect the negative lead to a good chassis ground.

(2) Disconnect the four-way connector going to the

servo (Fig. 12). Test pin 2 of the main harness four-

way connector for battery voltage. If not OK go to

step 3. If voltage is OK go to step 4.

(3) Perform the following tests.

(a) Disconnect the six-way connector at the stop

lamp switch and test pin 1 of the main harness for

battery voltage. If voltage is OK perform the stop

lamp switch test.

(b) If the stop lamp switch tests OK; repair wire

between the servo and the stop lamp switch.

(c) If no voltage at pin 1 at the 6-way stop lamp

connector, remove the vehicle speed control switch

and disconnect the four-way connector. Test pin 1

of main harness for battery voltage.

(d) If voltage is OK perform the vehicle speed

control switch test.

(e) If vehicle speed control switch is OK, test

continuity across the clockspring.

(f) If clockspring OK, repair as required, wire be-

tween stop lamp switch and clockspring.

(g) If no voltage at pin 1 of the 4-way vehicle

speed control switch connector.

• Test for battery voltage between the ignition and

the fuse

• If voltage OK, check fuse

• If fuse OK, repair wire between fuse and clock-

spring

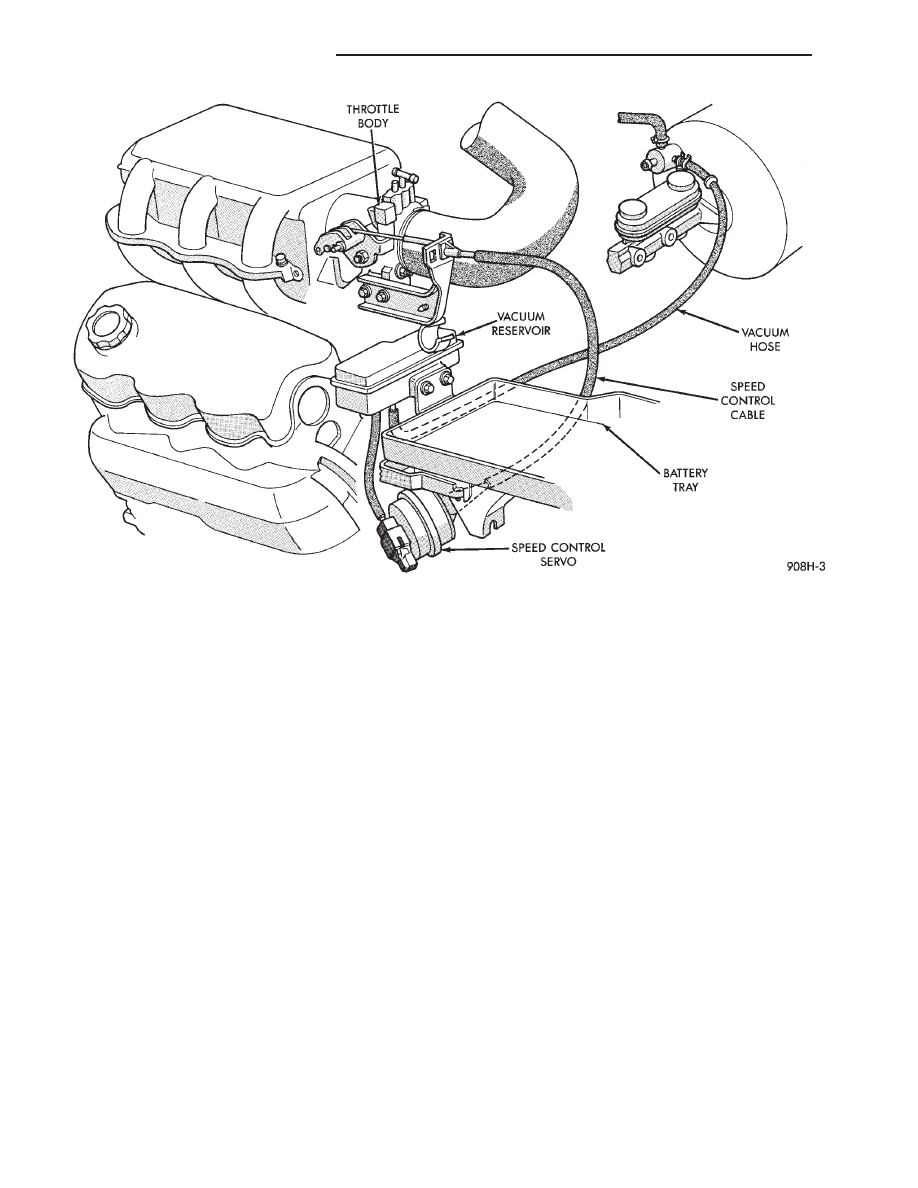

Fig. 7 Vehicle Speed Control—AC & AY Bodies with 3.0L

8H - 4

VEHICLE SPEED CONTROL

Ä

(4) Connect a jumper wire between pin 2 of the

four-way servo connector of the main harness and

pin 2 of the vehicle speed control servo (Fig. 12). The

other three pins from the servo should show battery

voltage. If not, replace the servo.

(5) Using an ohmmeter, connect one lead to a good

body ground and the other lead touch pin 1 in the

four-way servo connector of the main harness. The

meter should show continuity. If not, repair the

ground circuit as necessary.

POWERTRAIN CONTROL MODULE ELECTRICAL

TEST

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG,

STEERING

WHEEL

OR

COLUMN

RE-

MOVAL PROCEDURES.

(1) Unplug 60-way connector from the powertrain

control module, located next to the battery (Fig. 13).

(2) Remove vehicle speed control switch. Refer to

Vehicle Speed Control Switch Removal. Disconnect

the 4-way connector.

(3) Using an ohmmeter test continuity between pin

23 of powertrain control module and pin 4 of the ve-

hicle speed control switch harness. Refer to Fig. 14

for controller terminal locations.

(a) If no continuity, repair wire circuit as neces-

sary.

(b) Continuity OK, refer to Vehicle Speed Con-

trol Switch Test.

(4) Connect the 4-way connector to vehicle speed

control switch.

(5) Connect negative lead of voltmeter to a good

body ground near the powertrain control module.

(6) Turn ignition switch ON.

(7) Place vehicle speed control switch in the OFF

position. Touch the positive lead of the voltmeter to

pin 53, the voltmeter should read 0 volts.

(8) Place vehicle speed control switch in the ON

position. Touch the positive lead of the voltmeter to

pin 53, the voltmeter should read battery voltage.

(9) If no voltage, repair the wire between pin 53

and pin 3 of the vehicle speed control servo (Fig. 6).

If voltage is OK go to step 8.

(10) Place vehicle speed control switch in the OFF

position. Touch the positive lead of the voltmeter to

pin 33, voltmeter should read 0 volts.

(11) Place vehicle speed control switch in the ON

position. Touch the positive lead of the voltmeter to

pin 33, the voltmeter should read battery voltage.

(12) If no voltage, repair the wire between pin 33

and pin 4 of the vehicle speed control servo (Fig. 6).

If voltage is OK go to step 11.

Fig. 8 Vehicle Speed Control—AC & AY Bodies with 3.3/3.8L

Ä

VEHICLE SPEED CONTROL

8H - 5

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст