Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 225

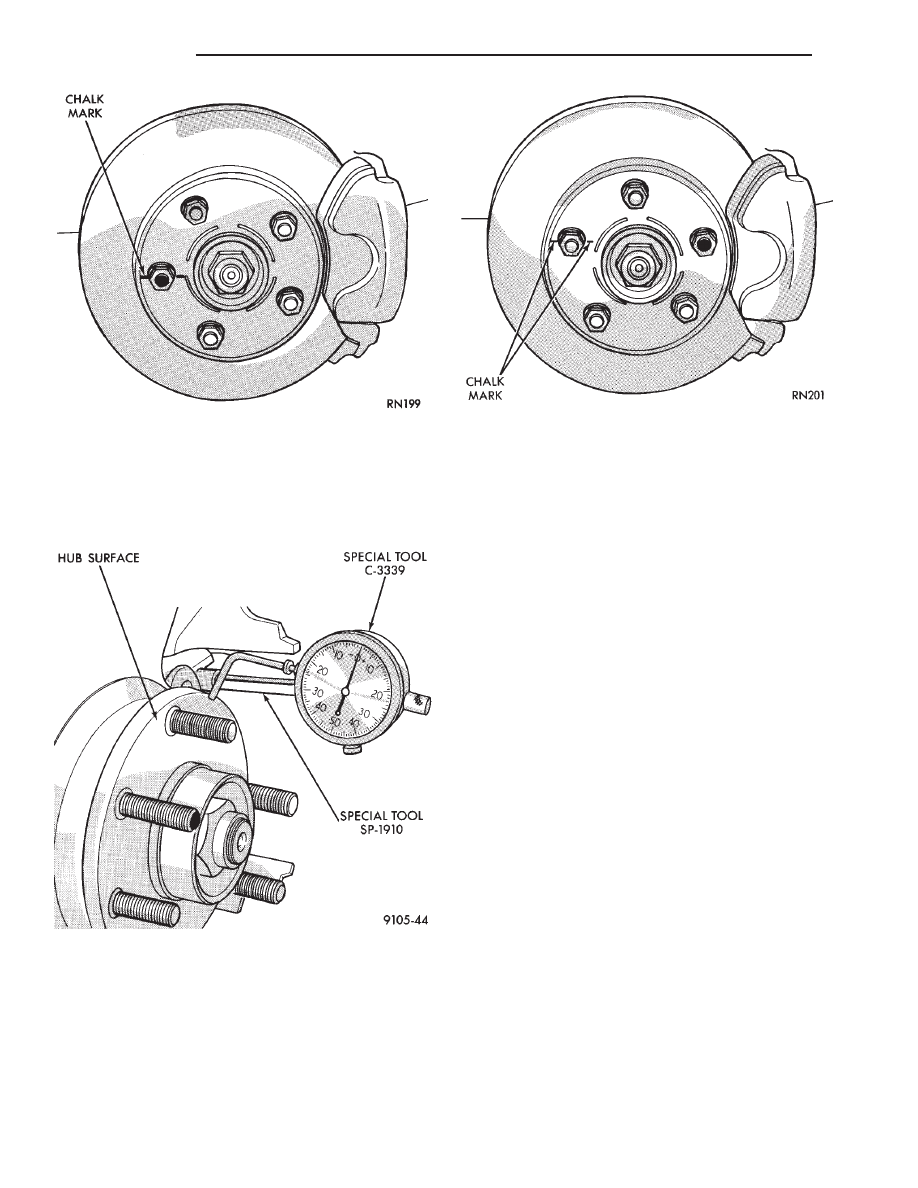

knuckle. Position stem so it contacts hub face near

outer diameter. Care must be taken to position stem

outside the stud circle but inside the chamfer on the

hub rim. Clean hub surface before checking. (See

Fig. 3)

Runout should not exceed 0.08 mm (0.003 inch). If

runout exceeds this specification, hub must be re-

placed. See Suspension Group 2. If hub runout does

not exceed this specification, install disc on hub with

chalk marks two wheel studs apart (Fig. 4). Tighten

nuts in the proper sequence and torque to specifica-

tions. Finally, check runout of disc to see if runout is

now within specifications.

If runout is not within specifications. Install a new

braking disc or reface disc, being careful to remove

as little as possible from each side of disc. Remove

equal amounts from each side of disc. Do not reduce

thickness below minimum thickness cast into the un-

machined surface of the rotor.

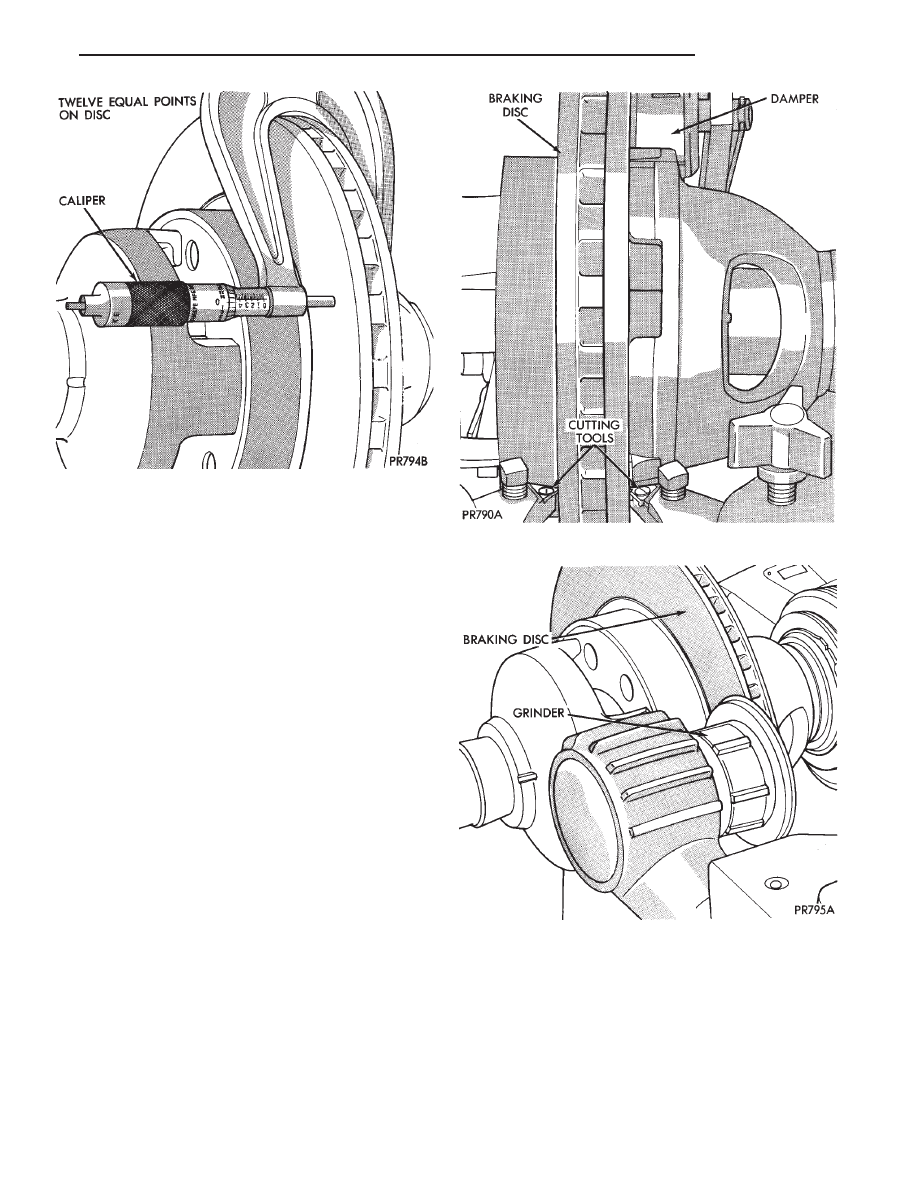

Thickness variation measurements of disc should

be made in conjunction with runout. Measure thick-

ness of disc at 12 equal points with a micrometer at

a radius approximately 25.4 mm (1 inch) from edge

of disc (Fig. 5). If thickness measurements vary by

more than 0.013 mm (0.0005 inch) disc should be re-

moved and resurfaced (Figs. 6 and 7), or a new disc

installed. If cracks or burned spots are evident in the

disc, disc must be replaced.

Light scoring and/or wear is acceptable. If heavy

scoring or warping is evident, the disc must be refin-

ished or replaced (See Refinishing/Refacing Braking

Disc). If cracks are evident in the disc, replace the

disc.

BRAKING DISC REMOVAL

(1) Raise vehicle on hoist or jackstands. Remove

wheel and tire assembly.

(2) Remove caliper assembly, as described under

Brake Shoe Removal in this Group, (but do not dis-

connect brake line). Suspend caliper from wire hook

or loop to avoid strain on flexible hose.

(3) Remove braking disc from the hub.

INSTALLING BRAKING DISC

(1) Slide braking disc on hub. Clean both sides of

braking disc with alcohol or suitable solvent.

(2) Install caliper assembly, as described in Brake

Shoe Installation paragraph.

Fig. 2 Marking Braking Disc and Wheel Stud

Fig. 3 Checking Hub for Runout

Fig. 4 Index Braking Disc and Wheel Stud

5 - 54

BRAKES

Ä

REFINISHING BRAKING DISC

REFACING BRAKING DISC

Refacing of the braking disc is not required each

time the shoe assemblies are replaced.

If the braking disc surface is deeply scored or

warped or there is a complaint of brake roughness or

pulsation the rotor should be resurfaced or refaced

(Figs. 6 and 7).

When refacing a braking disc the required 0.10

mm (0.004 inch) TIR (Total Indicator Reading) and

0.013 mm (0.0005 inch) thickness variation limits

MUST BE MAINTAINED. Extreme care in the op-

eration of braking disc turning equipment is re-

quired.

The collets, shafts and adapters used on the brake

lathe and the bearing cups in the rotor MUST be

clean and free from any chips or contamination.

When mounting the disc on the brake lathe, strict

attention to the brake lathe manufacturer’s operat-

ing instructions is required.

If the disc is not mounted properly the run-out will

be worse after refacing than before refacing.

The use of a double straddle cutter (Fig. 6) that

machines both sides of the disc at the same time is

highly recommended.

RESURFACING BRAKING DISC

This operation can be used when disc surface is

rusty, has lining deposits or excessive runout or

thickness variation is evident.

A sanding disc attachment will remove surface con-

tamination without removing much braking disc ma-

terial.

It will generally follow variations in thickness that

are in the disc.

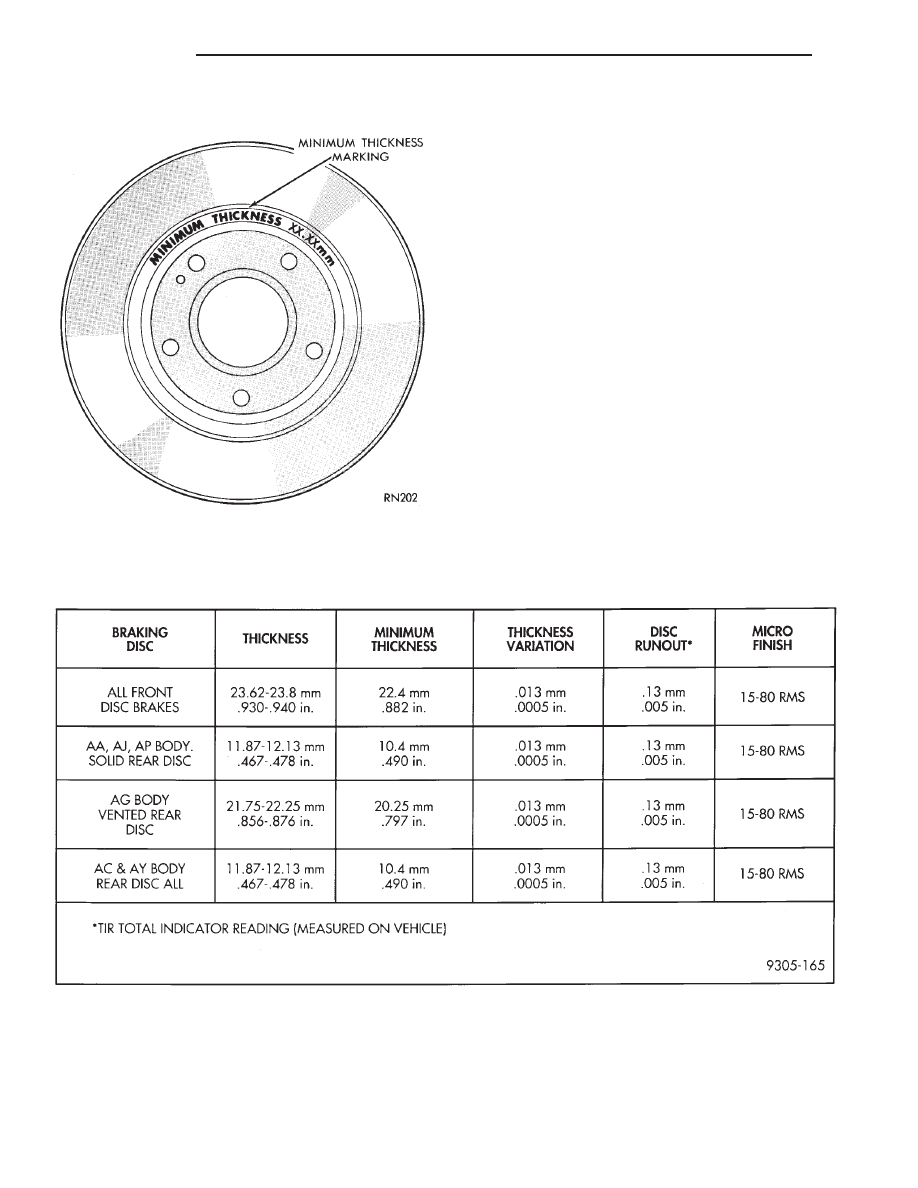

The following chart shows the location of measure-

ments and specifications when servicing the braking

disc.

All braking discs have markings for minimum

allowable thickness cast on an un-machined sur-

face of the braking disc (Fig. 8). The thickness

Fig. 5 Checking Disc for Thickness

Fig. 6 Refacing Braking Disc

Fig. 7 Resurfacing Braking Disc (Final Finish)

Ä

BRAKES

5 - 55

markings may be located on the disc as shown

in (Fig. 8) or on an alternate surface.

This marking includes 0.76 mm (0.030 inch) allow-

able

disc

wear

beyond

the

recommended

0.76

mm(0.030 inch) of disc refacing.

Fig. 8 Minimum Thickness Markings

BRAKING DISC (ROTOR) REFINISHING LIMITS

5 - 56

BRAKES

Ä

PARKING BRAKES

INDEX

page

page

Adjust Parking Brake (AG & AJ Body)

. . . . . . . . 61

General Information

. . . . . . . . . . . . . . . . . . . . . . . 57

Installing Parking Brake Front Cable (AA, AC, AP

AY Body)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Installing Parking Brake Shoes

. . . . . . . . . . . . . . 64

Parking Brake Hand Lever Assembly Removal and

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Rear Parking Brake Cable Installation

. . . . . . . . . 62

Rear Parking Brake Cable Removal (AA, AC, AP,

AY Body)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Removal and Installation Parking Brake Shoes

. . 63

Removing Parking Brake Front Cable (AA, AC, AP,

AY Body)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Self Adjusting Procedures (AG & AJ Body)

. . . . . 61

Service Procedures

. . . . . . . . . . . . . . . . . . . . . . . 57

GENERAL INFORMATION

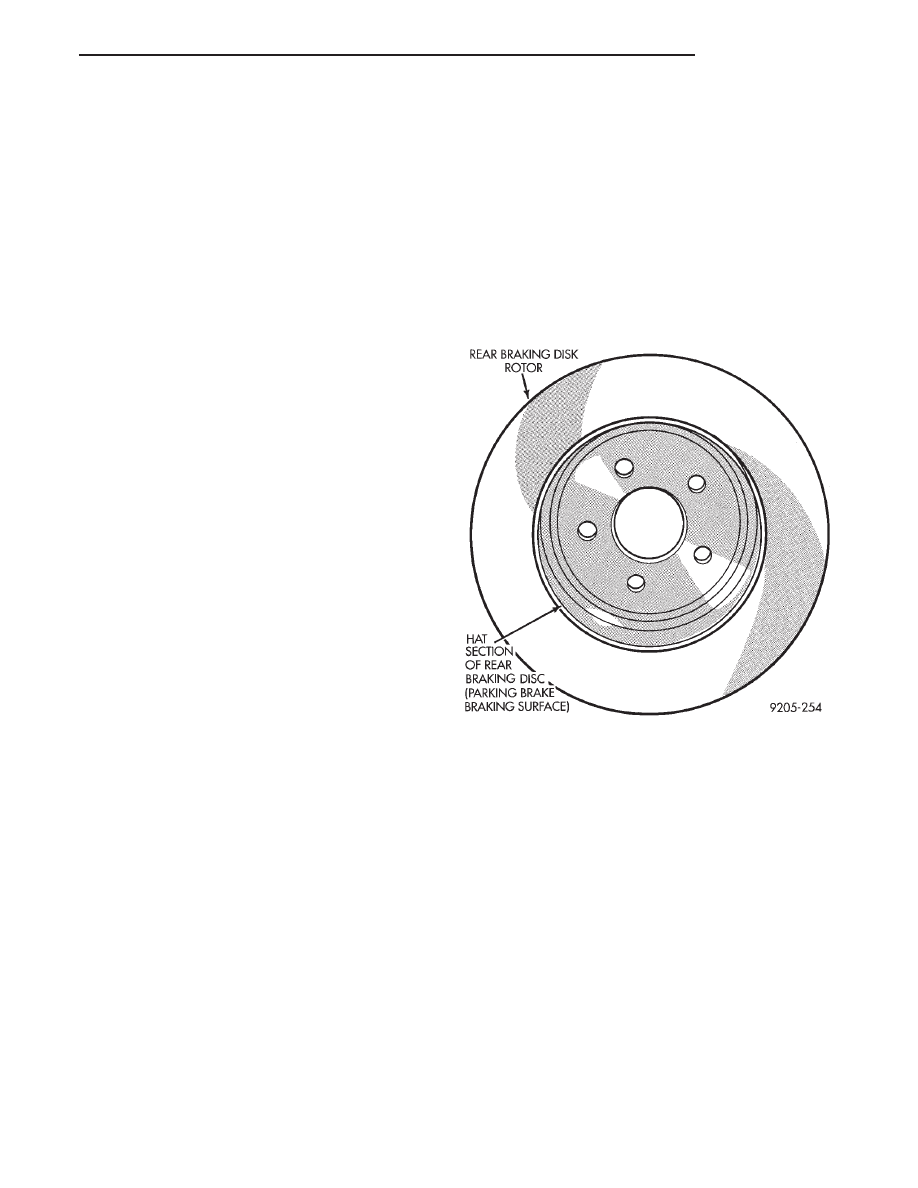

The parking brake mechanism on vehicles with

rear disc brake applications. Consists of a small duo-

servo brake which is mounted to the adapter. The

hat (center) section (Fig. 1) of the rear rotor serves as

the braking surface (drum) for the parking brakes.

On AA, AC, AP, AY body vehicles with rear disc

brake applications, the parking brake cable system is

similar in design to the drum brake parking brake

system.

The parking brake system on the AG and AJ body

vehicles is a 2 cable design. One individual park

brake cable operates each rear park brake mecha-

nism, and brake application is balanced by an equal-

izer at the park brake lever.

On rear drum brake applications, the rear wheel

service brakes also act as parking brakes. The rear

drum brake shoes are mechanically operated by an

internal lever and strut connected to a flexible steel

cable. The wheel brake cables are joined to an inter-

mediate cable which attaches to the front cable lead-

ing to the foot lever (Figs. 2, 3 and 4).

SERVICE PROCEDURES

ADJUSTING PARKING BRAKE

AP, AA, AC & AY (WITH FOOT LEVER)

The service brakes must be properly adjusted be-

fore adjusting the parking brake.

Release the parking brake lever then back-off

parking brake cable adjustment so there is slack in

the cable (Figs. 2 and 3).

Before loosening cable adjusting nut, clean threads

with a wire brush, and lubricate with Mopar Multi-

Purpose grease on equivalent.

The rear brakes adjust every time you depress the

brake pedal.

Adjust the parking brake after service brake ad-

justment by tightening the adjusting nut until a

slight drag is felt while rotating the wheels.

Loosen the cable adjusting nut until both rear

wheels can be rotated freely, then back-off the cable

adjusting nut two full turns.

Apply and release the parking brake several times

to see that the rear wheels rotate freely without

dragging.

AG AND AJ BODY (WITH HAND LEVER)

The parking brake hand lever assembly contains a

self adjuster for the cable system. Routine parking

brake adjustment is no longer required (Fig. 5).

Fig. 1 Drum In Hat Braking Disc

Ä

BRAKES

5 - 57

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст