Infiniti FX35 / FX45. Manual — part 281

CO-54

< SERVICE INFORMATION >

[VK45DE]

THERMOSTAT AND WATER CONTROL VALVE

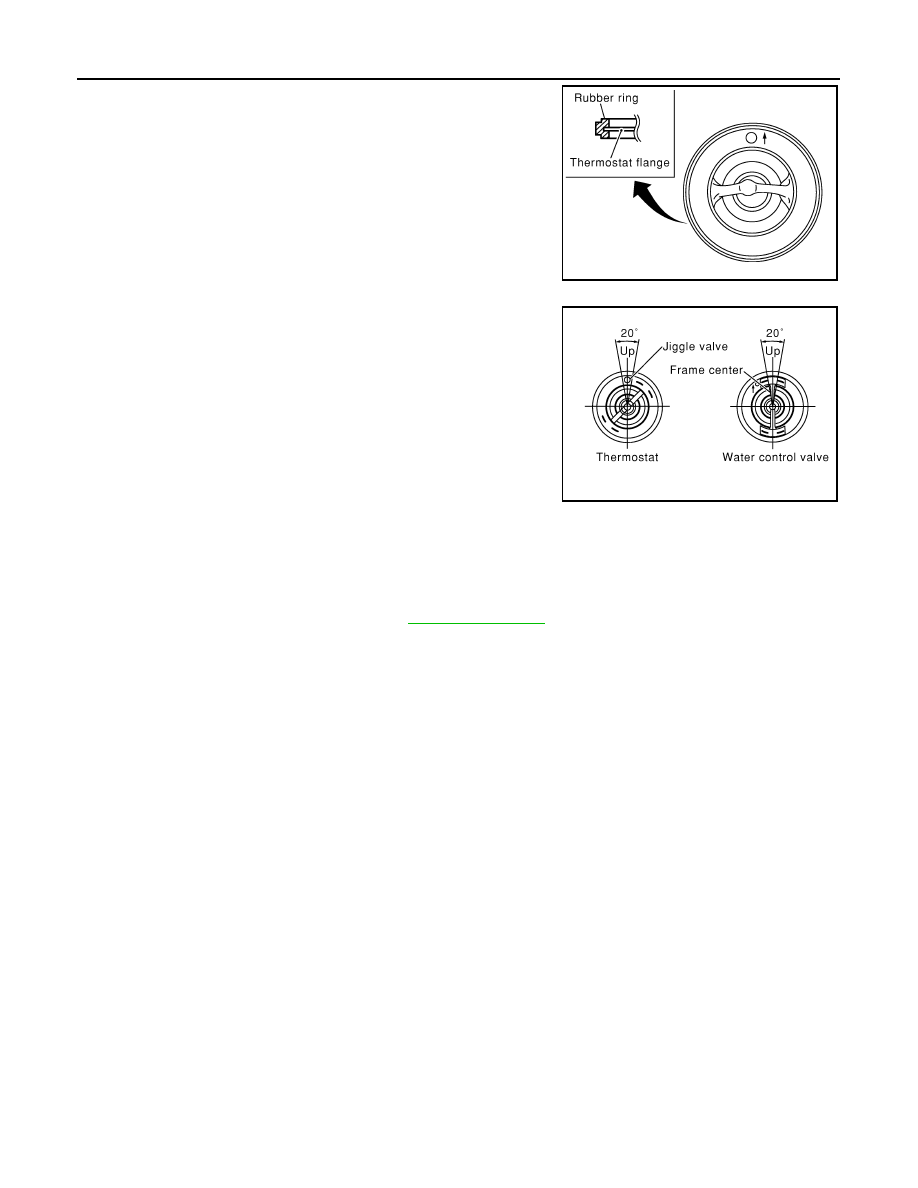

• Install thermostat and water control valve with the whole circumfer-

ence of each flange part fit securely inside rubber ring. (The exam-

ple in the figure shows thermostat.)

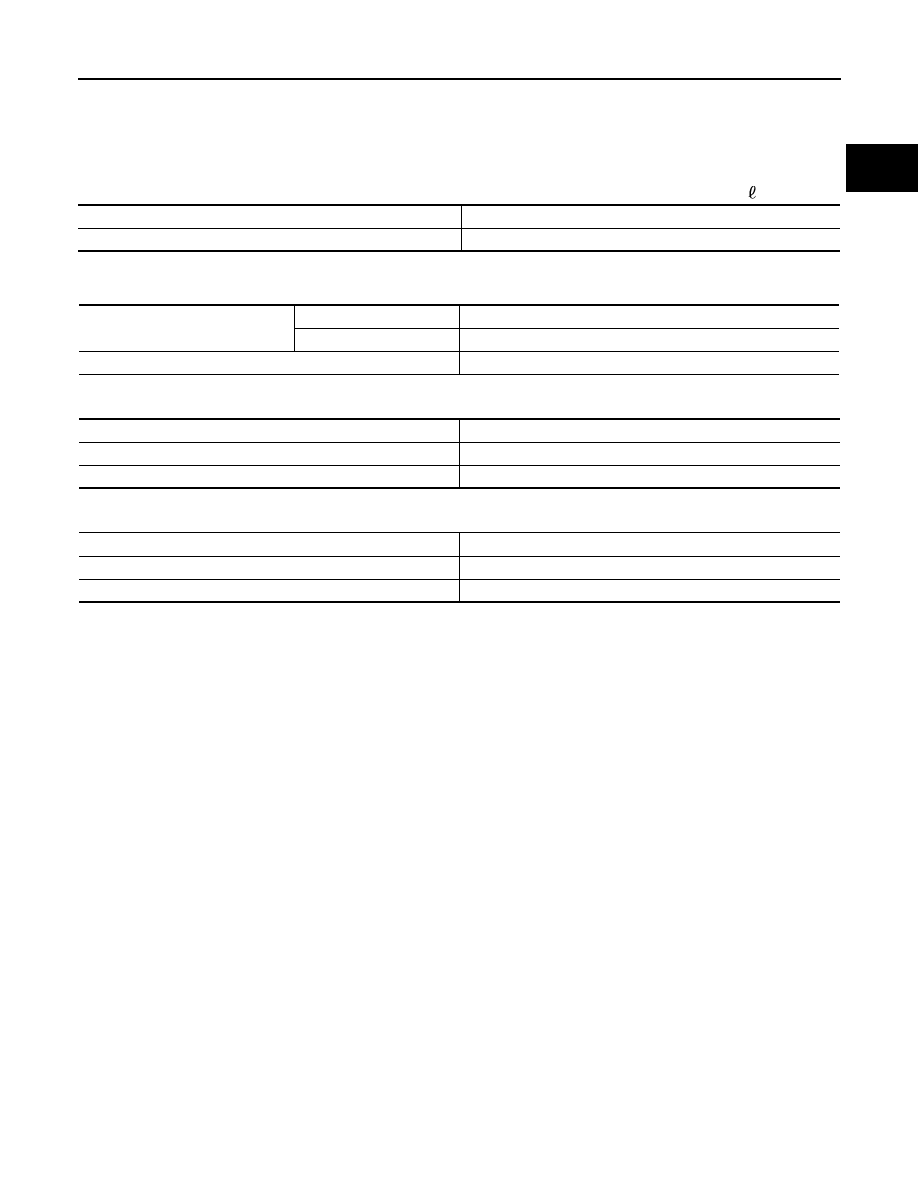

• Install thermostat with jiggle valve facing upwards. (The position

deviation may be within the range of

±

10 degrees)

• Install water control valve with the up-mark facing up and the frame

center part facing upwards. (The position deviation may be within

the range of

±

10 degrees)

Water Outlet Pipe and Heater Pipe

First apply a neutral detergent to O-rings, then quickly insert the insertion parts of the water outlet pipe and

heater pipe into the installation holes.

INSPECTION AFTER INSTALLATION

• Check for leaks of engine coolant using radiator cap tester adapter (commercial service tool) and radiator

cap tester (commercial service tool). Refer to

.

• Start and warm up engine. Visually check if there is no leaks of engine coolant.

PBIC0157E

PBIC0158E

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-55

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit

INFOID:0000000001325886

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit:

(US qt, Imp qt)

RADIATOR

Unit: kPa (kg/cm

2

, psi)

THERMOSTAT

WATER CONTROL VALVE

Engine coolant capacity [With reservoir tank at (“MAX” level)]

10.0 (10-5/8, 8-3/4)

Reservoir tank engine coolant capacity (at “MAX” level)

0.8 (7/8, 3/4)

Radiator cap relief pressure

Standard

78 - 98 (0.8 - 1.0, 11 - 14)

Limit

59 (0.6, 9)

Leakage testing pressure

157 (1.6, 23)

Valve opening temperature

80 - 84

°

C (176 - 183

°

F)

Maximum valve lift

More than 10 mm/95

°

C (0.39 in/203

°

F)

Valve closing temperature

77

°

C (171

°

F)

Valve opening temperature

93.5 - 96.5

°

C (200 - 206

°

F)

Maximum valve lift

More than 8 mm/108

°

C (0.315 in/226

°

F)

Valve closing temperature

90

°

C (194

°

F)

DI-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION

DI

A

B

DI

N

O

P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION . . . . . . .

DTC INDEX . . . . . . . . . . . . . . ..

U1000 - U1010 . . . . . . . . . . . . . . ..

B2202 - B2205 . . . . . . . . . . . . . . ..

C1B00 - C1B03 . . . . . . . . . . . . . .....

PRECAUTION . . . . . . . . . . . . . .

COMBINATION METERS . . . . . . . . ...

System Description . . . . . . . . . . . . ...

Component Parts and Harness Connector Loca-

tion . . . . . . . . . . . . . . . . . . ....

Arrangement of Combination Meter . . . . . . ..

Circuit Diagram . . . . . . . . . . . . . ...

Wiring Diagram - METER - . . . . . . . . . .

Terminal and Reference Value for Combination

Meter . . . . . . . . . . . . . . . . . ...

Terminal and Reference Value for Unified Meter

and A/C Amp . . . . . . . . . . . . . . ...

Self-Diagnosis Mode of Combination Meter . . .

CONSULT-III Function (METER/M&A) . . . . ...

Trouble Diagnosis . . . . . . . . . . . . ...

Symptom Chart . . . . . . . . . . . . . ...

Power Supply and Ground Circuit Inspection . . .

Vehicle Speed Signal Inspection . . . . . . . .

Engine Speed Signal Inspection . . . . . . . .

Engine Coolant Temperature Signal Inspection . ..

Fuel Level Sensor Signal Inspection . . . . . ...

Fuel Gauge Pointer Fluctuates, Indicator Wrong

Value or Varies . . . . . . . . . . . . . .

Fuel Gauge Does Not Move to FULL Position . .

Odo/Trip Meter and Illumination Control Switch In-

spection . . . . . . . . . . . . . . . . ...

Electrical Component Inspection . . . . . . . .

Removal and Installation of Combination Meter . .

Disassembly and Assembly of Combination Meter

.

Removal and Installation of Odo/Trip Meter and Il-

lumination Control Switch . . . . . . . . . .

UNIFIED METER AND A/C AMP . . . . . ..

System Description . . . . . . . . . . . . ..

Schematic . . . . . . . . . . . . . . . .

CONSULT-III Function (METER/M&A) . . . . .

Power Supply and Ground Circuit Inspection . . ..

DTC [U1000] CAN Communication Circuit . . . ..

DTC [B2202] Meter Communication Circuit . . .

DTC [B2205] Vehicle Speed Circuit . . . . . .

Removal and Installation of Unified Meter and A/C

Amp . . . . . . . . . . . . . . . . . . .

WARNING LAMPS . . . . . . . . . . .

System Description . . . . . . . . . . . . ..

Schematic . . . . . . . . . . . . . . . .

Wiring Diagram - WARN - . . . . . . . . . ...

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) . . . . . . . . . . . . . . . ..

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) . . . . . . . . . . ..

Component Inspection . . . . . . . . . . . .

A/T INDICATOR . . . . . . . . . . . .

System Description . . . . . . . . . . . . ..

Wiring Diagram - AT/IND - . . . . . . . . . ...

A/T Indicator Is Malfunction . . . . . . . . . .

WARNING CHIME . . . . . . . . . . . .

System Description . . . . . . . . . . . . ..

Component Parts and Harness Connector Loca-

tion . . . . . . . . . . . . . . . . . . ...

Schematic . . . . . . . . . . . . . . . .

Wiring Diagram - CHIME - . . . . . . . . . ...

Terminal and Reference Value for BCM . . . . ..

Terminal and Reference Value for Unified Meter

and A/C Amp. . . . . . . . . . . . . . . ..

Terminal and Reference Value for Combination

Meter . . . . . . . . . . . . . . . . . ...

DI-2

CONSULT-III Function (BCM) . . . . . . . ....

Trouble Diagnosis . . . . . . . . . . . . ...

Symptom Chart . . . . . . . . . . . . . ...

Power Supply and Ground Circuit Inspection . . .

Combination Meter Buzzer Circuit Inspection . . .

Front Door Switch (Driver Side) Signal Inspection ...

Key Switch Signal Inspection (Without Intelligent

Key) . . . . . . . . . . . . . . . . . ....

Lighting Switch Signal Inspection . . . . . . ...

Seat Belt Buckle Switch (Driver Side) Signal In-

spection . . . . . . . . . . . . . . . . ..

Component Inspection . . . . . . . . . . ....

LANE DEPARTURE WARNING SYSTEM . .

Precaution for Lane Departure Warning (LDW)

system . . . . . . . . . . . . . . . . ....

System Description . . . . . . . . . . . . .

Action Test . . . . . . . . . . . . . . . ..

Camera Aiming Adjustment . . . . . . . . ....

Component Parts and Harness Connector Loca-

tion . . . . . . . . . . . . . . . . . . ..

Schematic . . . . . . . . . . . . . . . ...

Wiring Diagram - LDW - . . . . . . . . . . .

Terminal and Reference Value for LDW Camera

Unit . . . . . . . . . . . . . . . . . . .

CONSULT-III Function (LDW) . . . . . . . ....

Trouble Diagnosis . . . . . . . . . . . . ...

Preliminary Check . . . . . . . . . . . . ..

Power Supply and Ground Circuit Inspection . . .

DTC [C1B00] CAMERA UNIT MALF . . . . . ..

DTC [C1B01] CAM AIMING INCMP . . . . . ...

DTC [C1B02] VHCL SPD DATA MALF . . . . ..

DTC [C1B03] ABNRML TEMP DETECT . . . ....

DTC [U1000] CAN COMM CIRCUIT . . . . . ..

DTC [U1010] CONTROL UNIT (CAN) . . . . ....

LDW Chime Circuit Inspection . . . . . . . ....

LDW Switch Circuit Inspection . . . . . . . ...

LDW Indicator Lamp Circuit Inspection . . . . ..

Turn Signal Input Inspection . . . . . . . . ...

Electrical Component Inspection . . . . . . .

Removal and Installation for LDW Camera Unit . .

Removal and Installation for LDW Chime . . . ...

Removal and Installation for LDW Switch . . . ...

CAN COMMUNICATION . . . . . . . . ...

System Description . . . . . . . . . . . . .

CAN Communication Unit . . . . . . . . . ...

COMPASS . . . . . . . . . . . . . . .

Precaution for Compass . . . . . . . . . . .

System Description . . . . . . . . . . . . .

Troubleshooting . . . . . . . . . . . . . ..

Zone Variation Setting Procedure . . . . . . ...

Calibration Procedure . . . . . . . . . . . .

Wiring Diagram - COMPAS - . . . . . . . . ..

Removal and Installation of Compass . . . . .

CLOCK . . . . . . . . . . . . . . . ..

Wiring Diagram - CLOCK - . . . . . . . . . .

Removal and Installation of Clock . . . . . . ...

REAR VIEW MONITOR . . . . . . . . .

System Description . . . . . . . . . . . ...

Component Parts and Harness Connector Loca-

tion . . . . . . . . . . . . . . . . . .

Schematic . . . . . . . . . . . . . . . .

Wiring Diagram - R/VIEW - . . . . . . . . ...

Terminal and Reference Value for Rear View

Camera Control Unit . . . . . . . . . . . .

CONSULT-III Function (REARVIEW CAMERA) ...

Side Distance Guideline Correction . . . . . ..

Power Supply and Ground Circuit Inspection . ...

Rear View Is Not Displayed with the A/T Selector

Lever in R-Position . . . . . . . . . . . .

The Rear View Image Is Distorted . . . . . .

Removal and Installation of Rear View Camera

Control Unit . . . . . . . . . . . . . . ...

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст